Better Decisions

The REFLEX ORI-AUDITOR™ allows for auditing of the data and process both at the time of transfer and with the use of the REFLEX ORI-BLOCK™ later at the Core Shed.

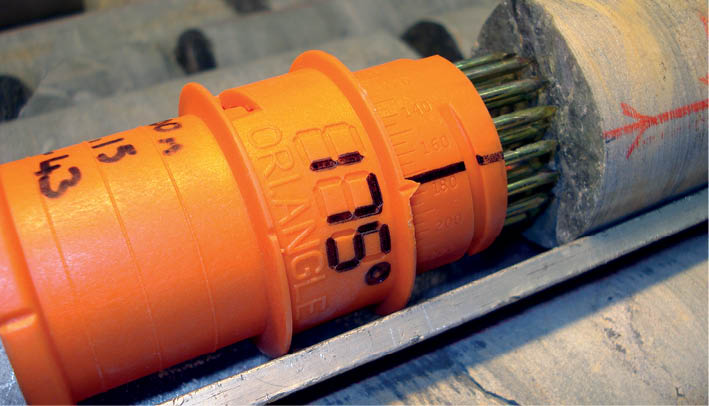

The REFLEX ORI-BLOCK™ provides off-site QA/QC auditability and the opportunity to correct data transfer errors at a later time. Assurance as to the accuracy of information, with precise data transfer, is critical to good and confident structural decision making. Maximize your opportunity for compliance with internationally recognized standards for reporting mineral resources and reserves such as the Australian JORC Code, the Canadian NI 43-101, the European PERC Standard and the South African SAMREC and SAMVAL codes.

The combined application of the REFLEX ORI-AUDITOR™ with the REFLEX ORI-BLOCK™ provides the assurance that the data on which these reports are based, is accurate and reliable.