Case Studies

August 3, 2021

Leading global mining-tech company IMDEX has combined two leading data analysis products to produce a powerful workflow that delivers results applicable across the mining value chain from exploration to production. The combination of IMDEX™ ioGAS™, the established leader in geoscience analysis, with IMDEX™ aiSIRIS™, the global leader in spectral mineralogy interpretation provides the user with a powerful solution to merge and analyse spectral mineralogy data with geochemical and other geological data sets. IMDEX™ has been working on the interoperability of the two products since it acquired AusSpec last year and with it, the aiSIRIS™ technology. AusSpec founder and director Dr […]

March 4, 2021

At least 120 countries and an increasing number of companies globally have committed to achieving net zero emissions by 2050, throwing the focus on the dramatic changes needed to achieve such an ambitious target. The International Energy Agency, in its World Energy Outlook 2020 report, said that reaching net zero emissions globally by 2050 would demand a set of dramatic actions over the next 10 years. Achieving a 40 per cent reduction in emissions by 2030 would require low-emission sources to provide nearly 75 per cent of global electricity generation in 2030 (up from less than 40 per cent in […]

January 4, 2021

Have you ever wondered about the diamonds in a diamond drill bit? Kelvin Brown, from IMDEX, has given this subject a lot of thought and he recently shared his ideas on what the future holds for drill bits and core sampling with GeoDrilling International. Unlike the James Bond theme song by Shirley Bassey, diamonds are not forever when it comes to diamond drilling. Companies continue to try to refine the synthetic diamond core bit, altering the size and concentration of the diamonds and the composition of the matrix, but as far as IMDEX global lead, Directional Drilling, Kelvin Brown is […]

November 27, 2019

The El Toqui Mining Project, operated by Laguna Gold, is located in the far south of Chile. Ground conditions and the presence of magnetic infastructure underground make a fast, gyro-based survey method critical for success.

September 9, 2019

At AKD Panama Corp’s project in Cobre mine, Panama, AMC BOS™ addressed problems with lost circulation, leading to improved productivity, reduced water and drilling fluids consumption.

March 27, 2019

The El Toqui Mining Project, operated by Laguna Gold, is located in the far south of Chile. Ground conditions and the presence of magnetic infastructure underground make a fast, gyro-based survey method critical for success.

February 27, 2019

IMDEX conducted controlled trials of the IMDEX MUD AID™ at a mine site. Over the course of the trial, the IMDEX MUD AID™ provided mud data that allowed drilling crews to be more responsive to changes in lifting capacity and solids content.

June 13, 2018

AMC Borehole Optimisation System™ (AMC BOS™) successfully controlled fault zones and changing formations at a gold exploration project in Chile. This innovative system was able to have a positive effect on productivity and reduce the consumption of mud and water by effectively managing and preventing lost circulation, high torque and borehole instability.

May 29, 2017

AMC BOS™ was a success at the Resolution Mine, saving a borehole that had been abandoned, reducing the costs and improving the productivity of the hole.

May 19, 2017

Published: CSIRO Mining Equipment, Technology and Services booklet, May 2017 Imdex Ltd is an ASX listed mining technology provider to the global minerals industry, headquartered in Perth, Western Australia. The company has operation in all key mining and exploration regions throughout Asia Pacific, Africa, Europe and the Americas. Imdex develops solutions to improve the process of identifying and extracting what is below the earth’s surface for drilling contractors and resource companies. Imdex aims to be a market leader in real-time subsurface intelligence solutions, through its AMC and REFLEX brands.

September 12, 2016

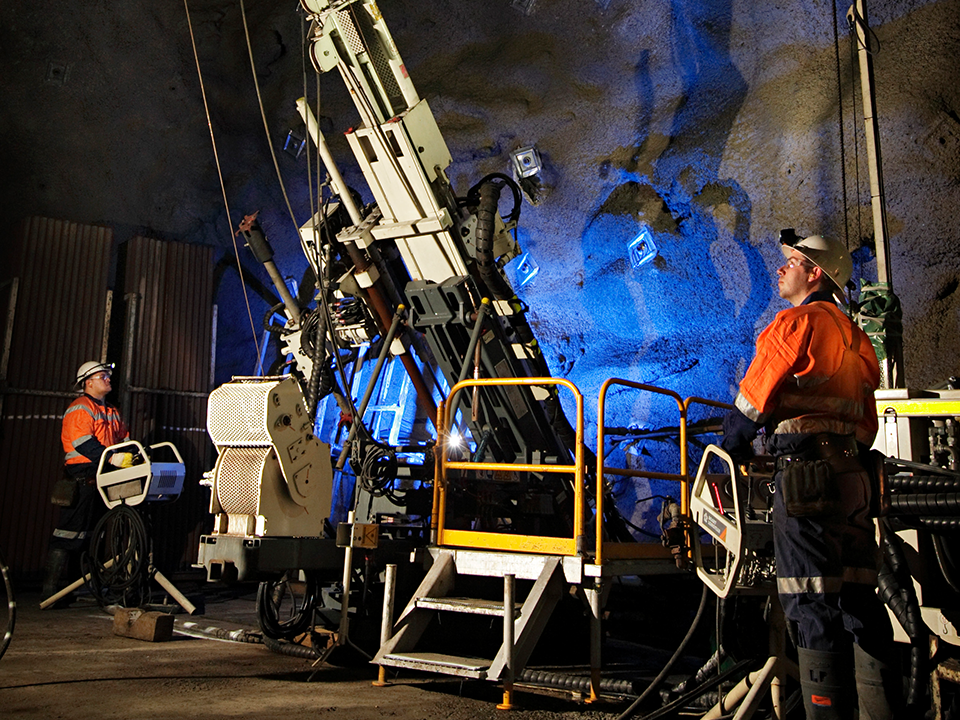

AMC BORE HOLE STABILISER™ successfully negated the need for traditional PVC casing at an underground mine in the Goldfields region of Western Australia.

March 17, 2016

The REFLEX IQ-LOGGER™ is the latest in core logging technology. The device is defining new processes of structural logging and revolutionising the data collection and interpretation practises of past.

July 18, 2014

A Chilean AMC SRU™ trial also demonstrated a significant reduction in water and mud consumption, together with other operating costs, when utilising the AMC SRU™ unit. The AMC SRU™ addressed the key challenges experienced at this site, where water access was limited and expensive.

December 6, 2013

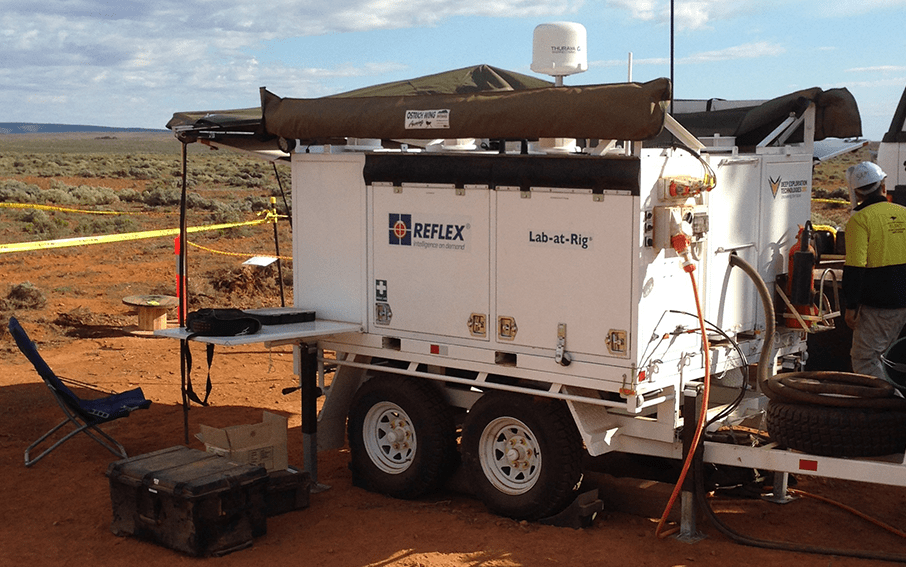

AMC SRU™ reduced the client’s operational costs and environmental impact on site in the Sandy Desert, East Pilbara Western Australia.